45 Years of Quality

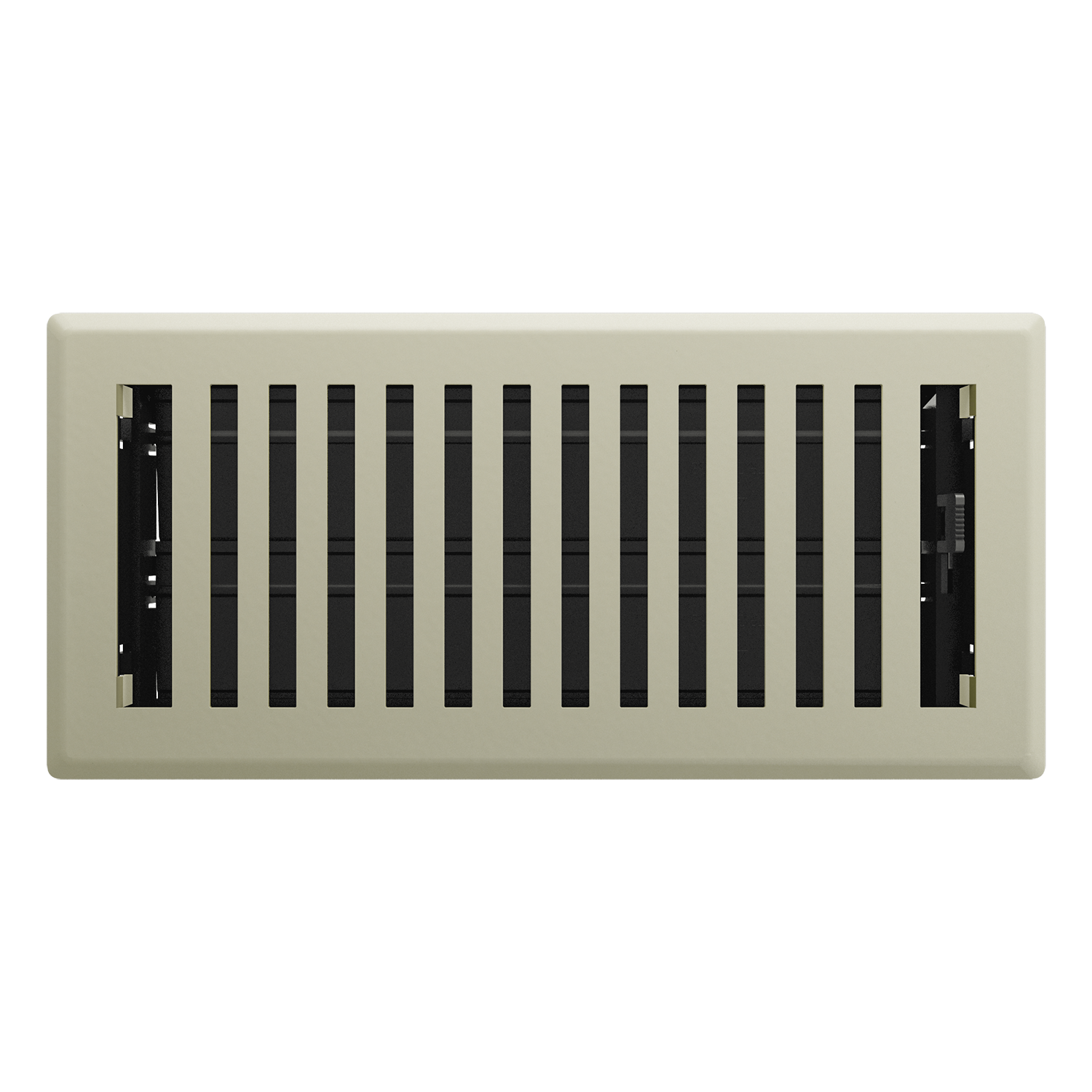

We design, manufacturer, assemble, and distribute over 7000 metal and plastic heating, air conditioning, ventilation, and building products for use in homes and commercial buildings. Maintenance, renovation, or construction - we've got what you need.